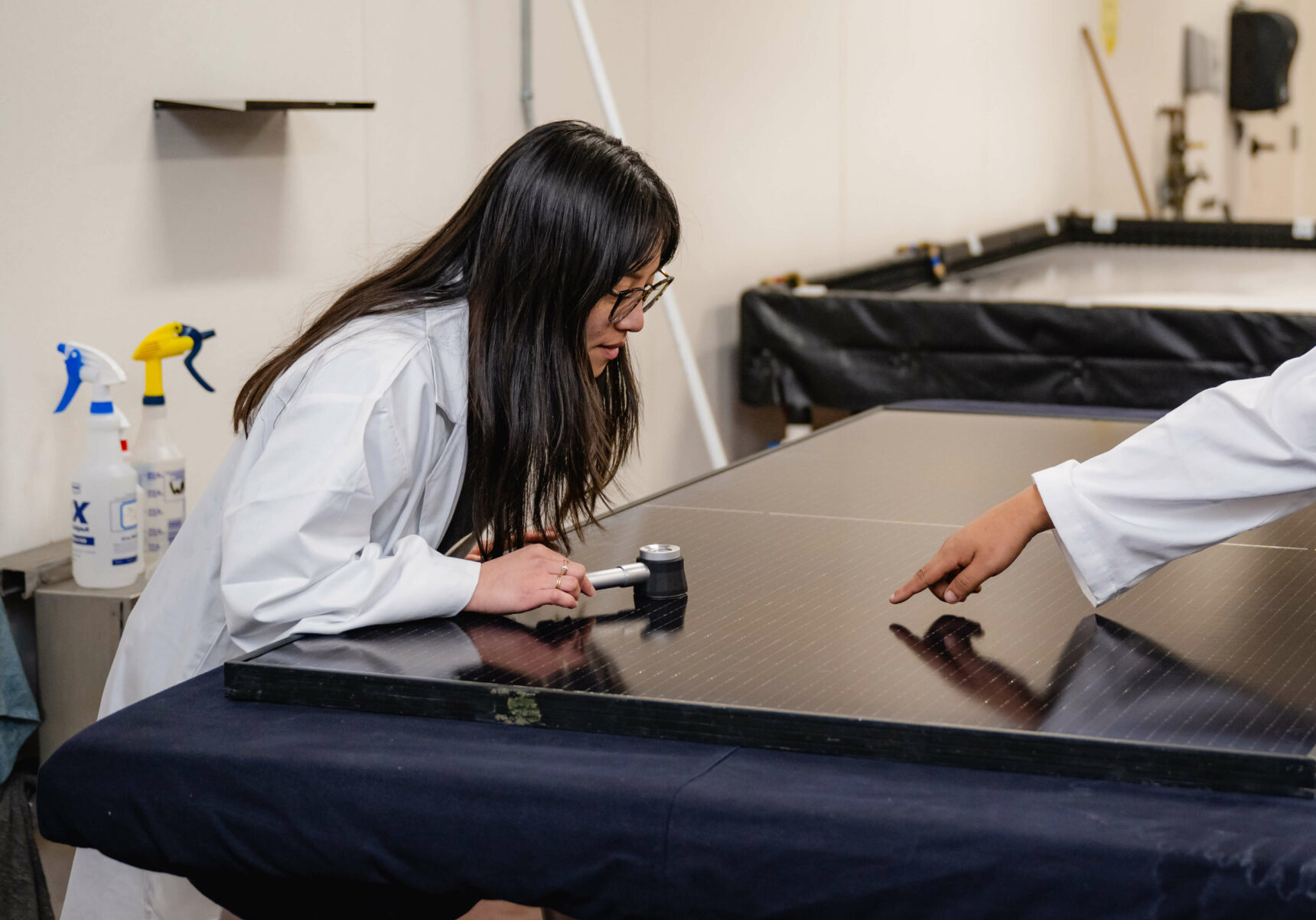

Researchers at the Fotovoltaica-UFSC recently designed a 100 kWp site to evaluate bifacial silicon PV module performance under Brazilian climatic conditions. Located in Florianópolis-SC, Brazil, the project uses large-format bifacial glass//glass modules with 2 mm heat-strengthened glass, installed across five single-axis tracking rows and one fixed-tilt system. Little did they know that they would actually be studying module glass breakage.

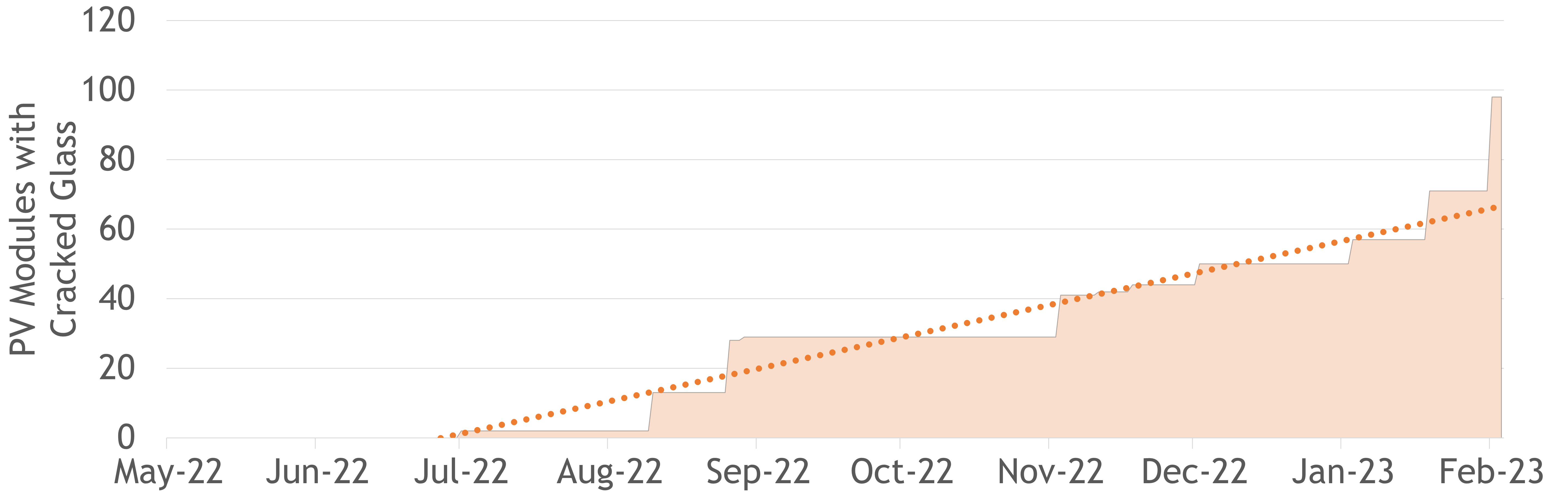

Not long after site commissioning, the researchers noticed glass cracks on the front or rear of some modules. Regular inspections were conducted and a trend of 14 broken modules per month was recorded over a seven-month period. Within nine months of site commissioning, over 50% of the installed modules had cracked glass. The weather monitoring data over this period did not show any temperature or wind event anomalies.

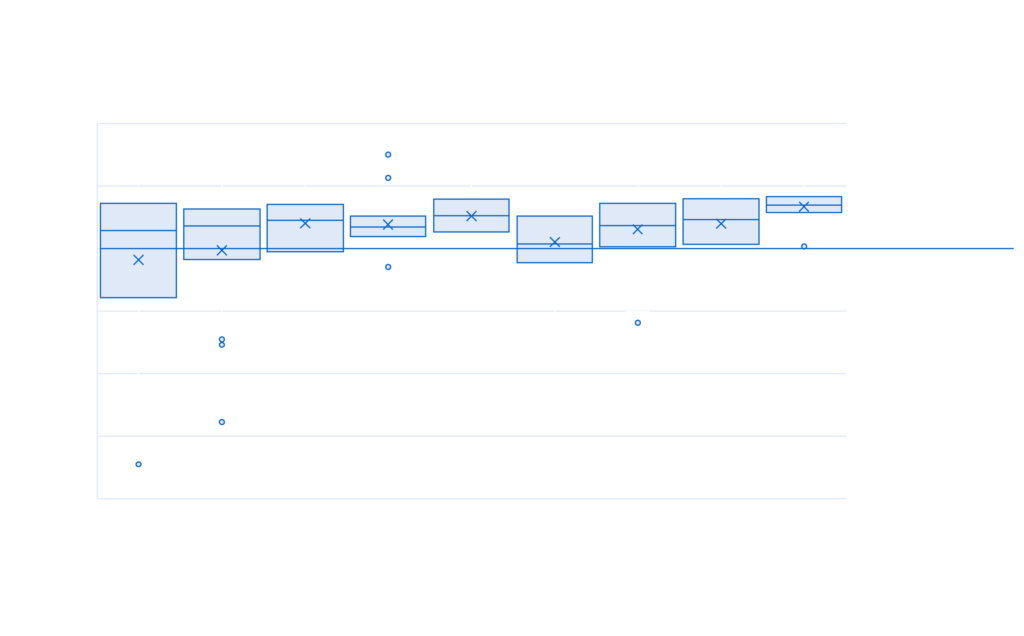

To date the glass cracks have not impacted system safety or performance. The researchers have thus far found no correlation between glass cracks and cell cracks on EL images, power degradation, or hot spots. But the long-term reliability of modules with broken glass is certainly at risk. The root cause analysis is still ongoing with the module and racking/tracker manufacturers involved.

This is not a unique case of module breakage in the solar industry. The Kiwa Group members have been contacted multiple times in the past year with reports of broken glass on PV sites. Tracker/racking compatibility with large-format modules is critical, and PVEL’s MSS testing on specific module and tracker/racking combinations provides site stakeholder confidence in avoiding these types of issues.