PVEL’s consistent approach to testing and benchmarking PV module reliability drives data-driven solar procurement and investments for developers, financiers, and asset owners.

Methodology

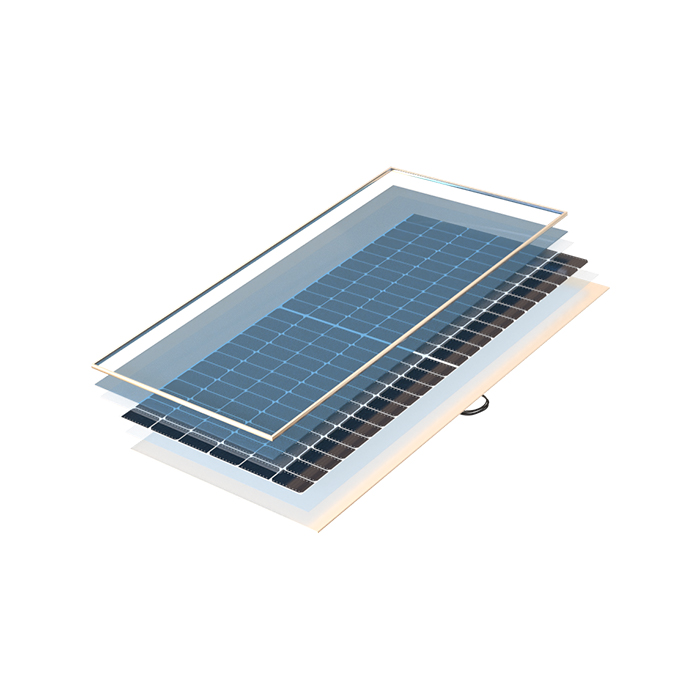

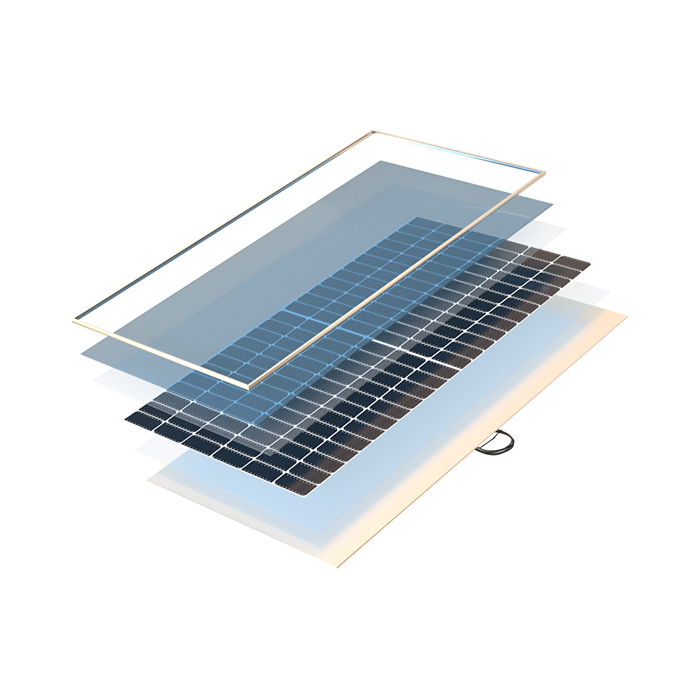

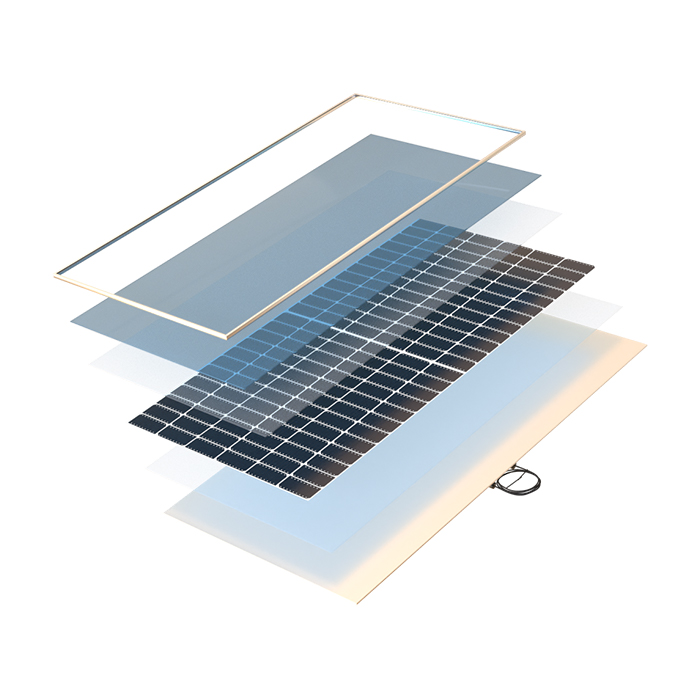

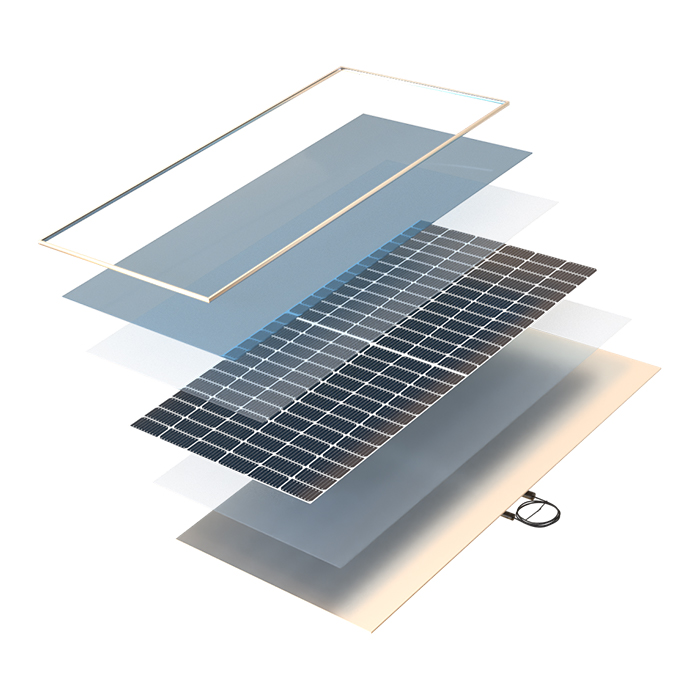

Testing Unique Bills of Materials

Although Top Performers are listed by model type, they represent unique bills of materials (BOMs) that PVEL has tested in our Product Qualification Program (PQP).

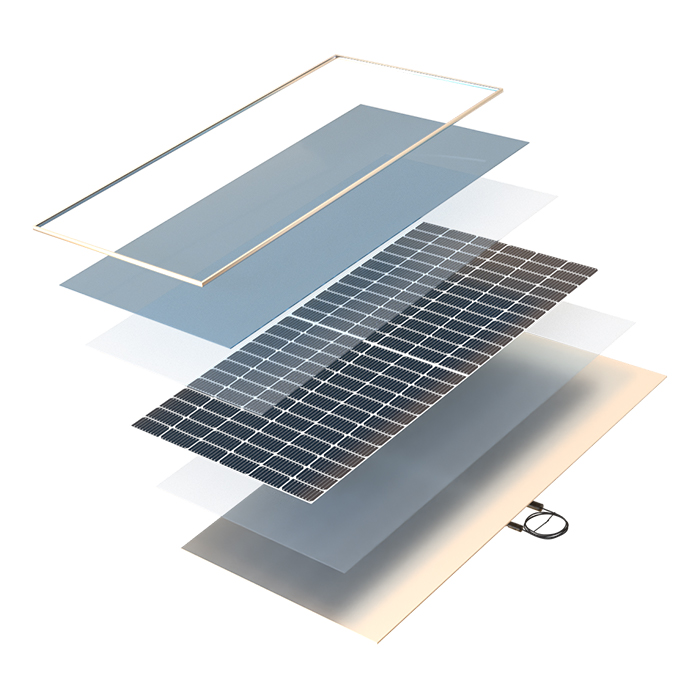

Aluminum Frame

View DetailsGlass & Glass Coating

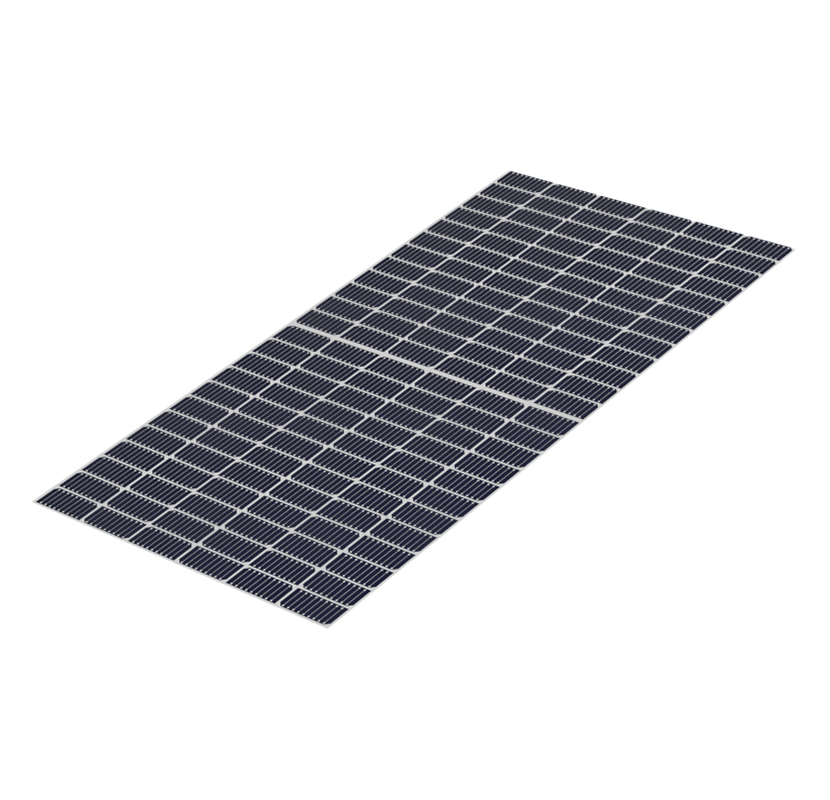

View DetailsSolar Cell

View DetailsBacksheet or Glass

View DetailsWhy BOM-Level Testing is Important

PVEL’s test results from the lab and field demonstrate that individual PV module components can dramatically affect product quality. PV modules with the exact same model type can be manufactured from completely different BOMs. Suppliers are free to mix-and-match integral materials – even cells – as long as all the components are listed in the model’s IEC certification report.

PVEL’s testing generates vital procurement intelligence.

While individual BOMs are not marketed to buyers, PQP reports clearly document the BOMs of each model that performed well in testing. PVEL’s downstream partners can leverage PQP reports to specify BOMs in supply agreements.

Who Qualifies for the Scorecard

To be eligible for the Scorecard, manufacturers must have:

Completed the factory witness within 18 months of 2022.

Submitted all modules to all reliabilty tests.

Submitted at least two factory-witnessed PV module samples per test sequence.

How BOMs are Scored

The 2022 PV Module Reliability Scorecard shows Top Performers for six PQP test categories.

Top Performers are determined by averaging the results of every BOM tested by PVEL that is sold under the same model type. Top Performers in each of the reliability tests appearing in the Scorecard must have < 2% power degradation following the particular test. PAN Performance Top Performers must place in the top quartile for energy yield in PVEL’s PVsyst simulations.

PVEL’s scoring methodology is consistent over time.

Click here to view past Scorecards.

An example of a module with high levels of degradation is provided for each reliability test, complete with electroluminescence (EL) images and flash test results on each reliability test result page, and visual inspection images where appropriate.

Not all products or model types are represented in every test. Manufacturers with top results can choose not to be listed in the Scorecard. In some cases, test results were not available at the time of publication.

Testing PV Module Reliability and Performance

PVEL’s PV Module PQP is a comprehensive suite of lab and field tests that assess the bankability of PV modules. Click here to view PQP test sequences. While the specific tests have changed over time, the same four principles have guided PVEL’s PQP since it was first established in 2012:

Empirical Data

The PQP provides empirical metrics for revenue and energy yield modeling.

Standard Processes

The PQP tests all BOMs in the same way with calibrated equipment and in consistent test environments.

No Hand-picked Samples

Auditors witness the production of all test samples and record BOM details.

Regular Program Updates

Test sequence updates provide data on new technologies and manufacturing techniques.

Go beyond model types. Procure PV modules with top-performing bills of materials.

Join PVEL’s downstream partner network.

Sign Up