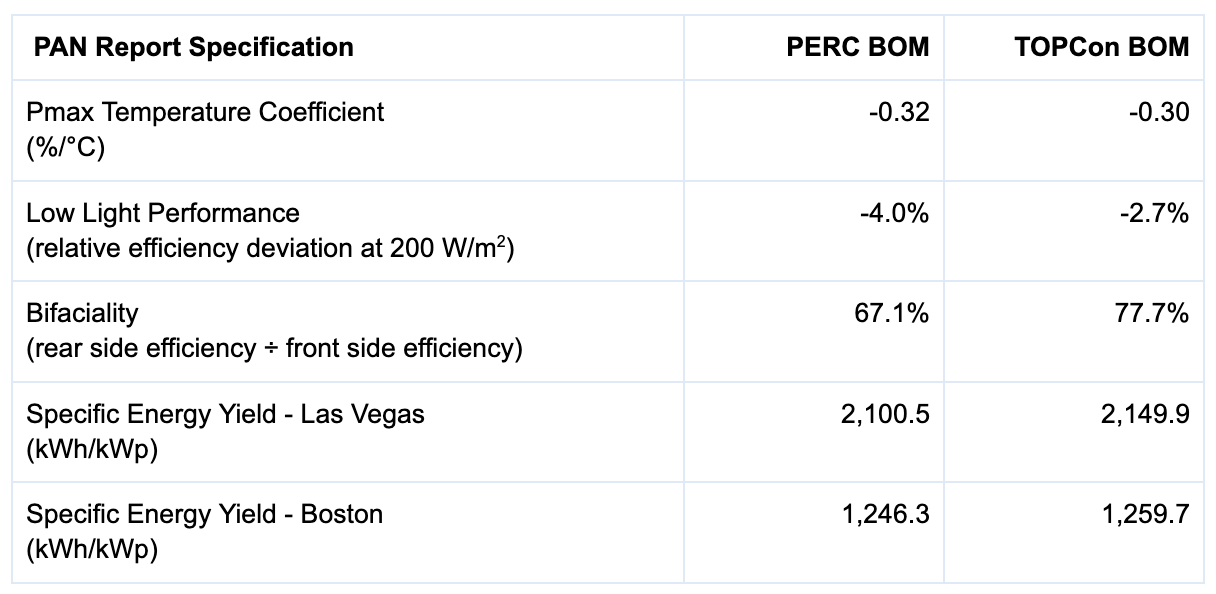

In their role as technical advisors, PI Berlin, a member of the Kiwa Group, often works with project stakeholders to review the module manufacturer’s PAN files. PI Berlin’s analysis has revealed that, while conservative values are occasionally used, more frequently, manufacturer-provided PAN files contain aspirational assumptions for low light performance, temperature coefficients and/or IAM (Incidence Angle Modifier) curves.

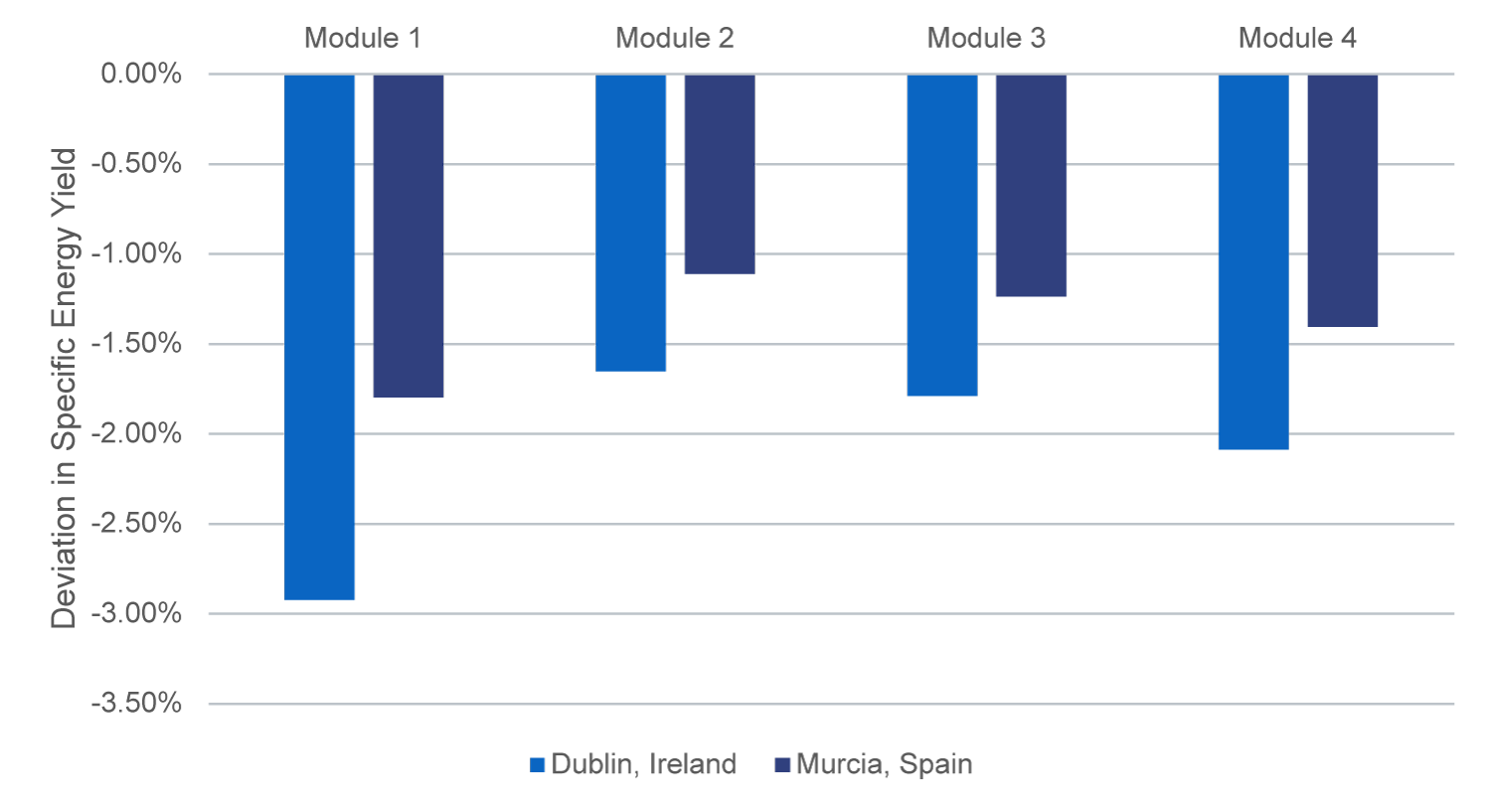

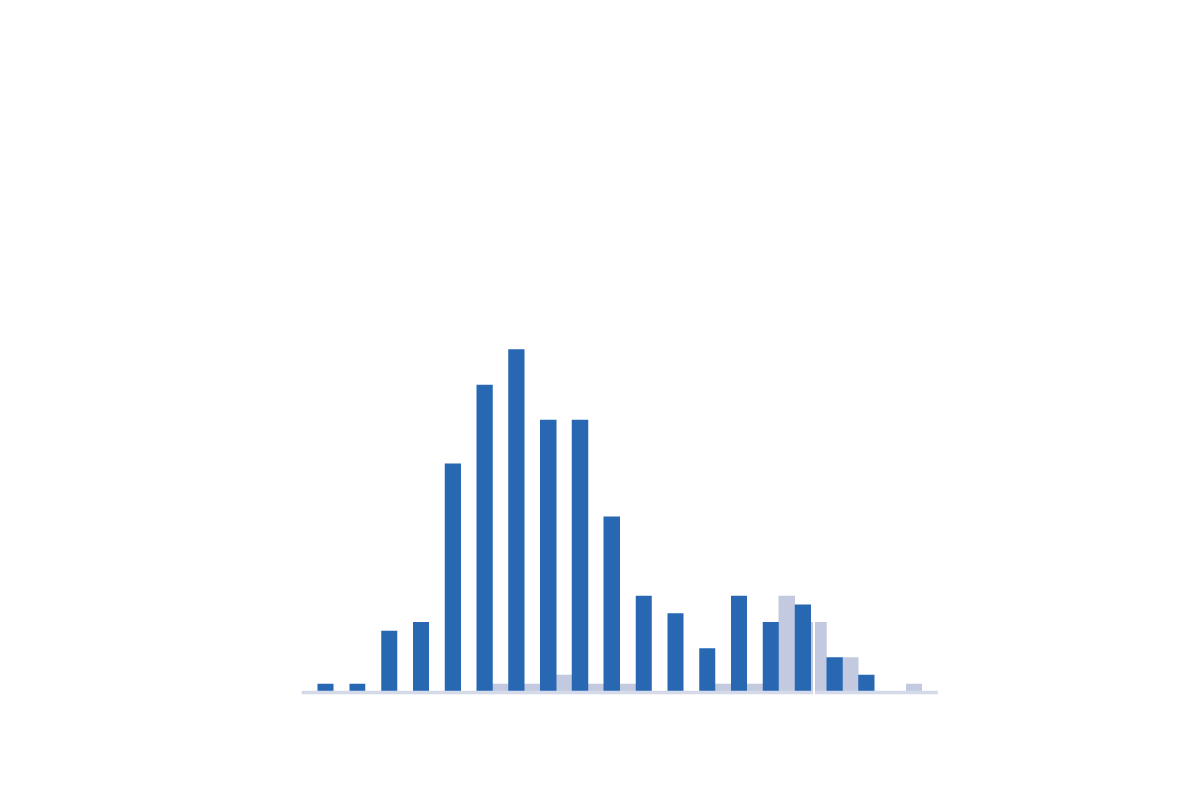

Four recent examples of this specifically related to low light performance are detailed here, taken from different modules being considered for four different projects. In these cases, PI Berlin was also shipped samples of the same modules to perform PAN measurements. The resultant measurement-based PAN files were compared to the manufacturer-supplied PAN files. To isolate the low light performance effects, all other PAN parameters were held constant between the two differently-sourced PAN files, which were then used in two PVsyst simulated sites. The site in Dublin, Ireland, has a higher frequency of low light conditions than the second site in Murcia, Spain, leading to more pronounced impacts of low light performance differences.

The results reveal that in all cases, the manufacturers’ low light performance assumptions were more aggressive than PI Berlin’s measurements on the same modules, with deviations in specific energy yield ranging from 1.1% to 2.9%. While these differences might initially seem negligible, using these manufacturer-provided PAN files for utility-scale sites would lead to significant overvaluation in financial models, likely leading to underperforming assets that do not achieve their expected energy yield.

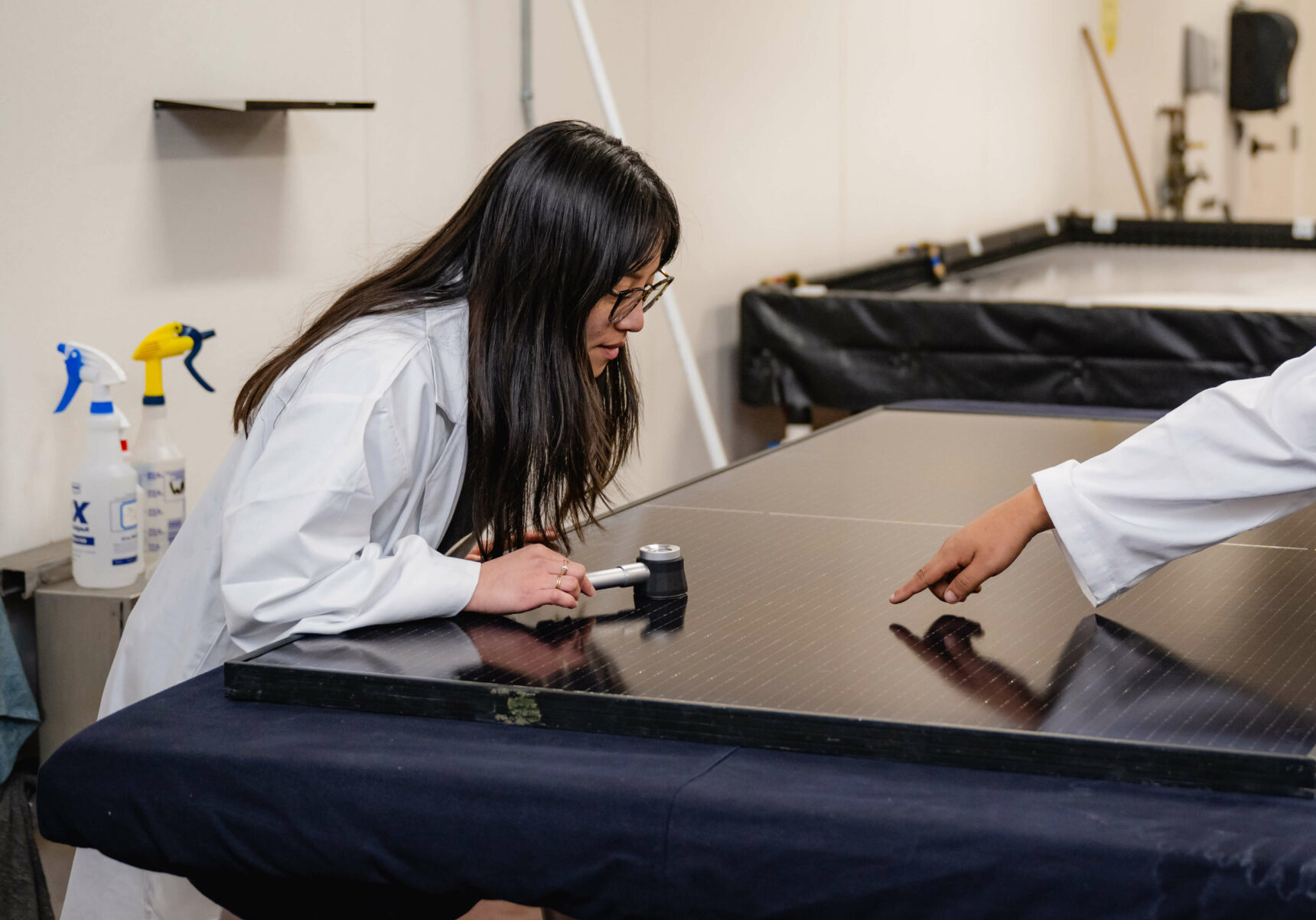

As part of Kiwa’s Module Procurement Best Practices, third-party PAN testing is strongly recommended, both during module qualification, which is achieved via PVEL’s PQP PAN testing, as well as during batch testing of modules being shipped to the project site, which is offered at all Kiwa Group labs.