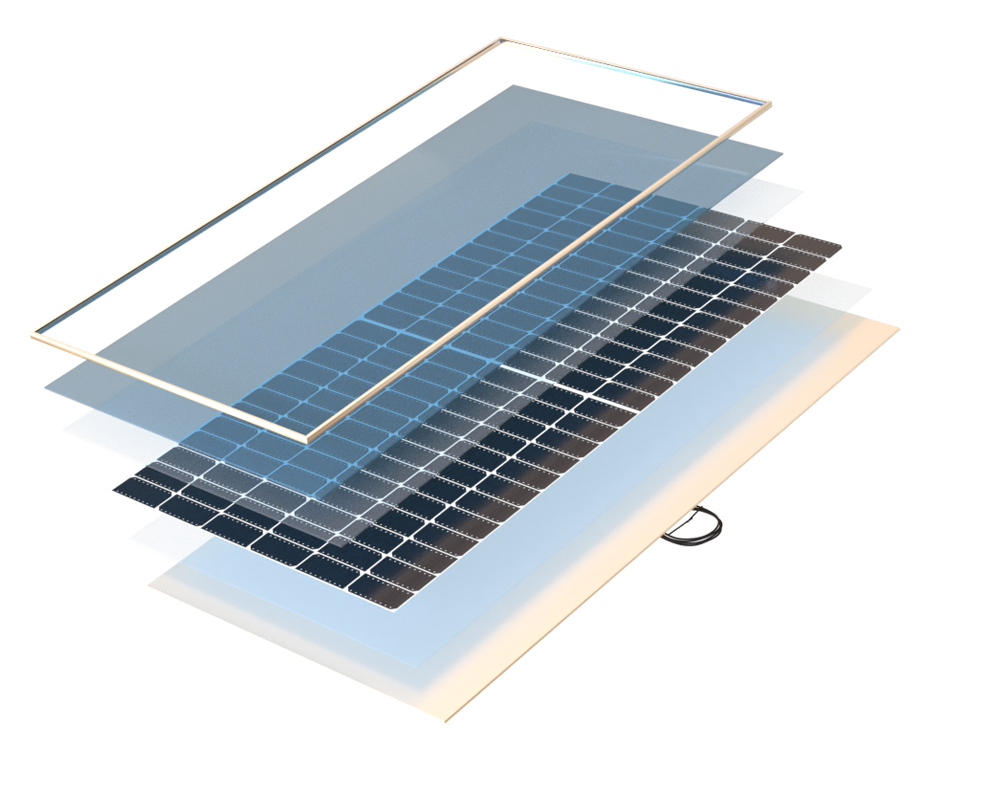

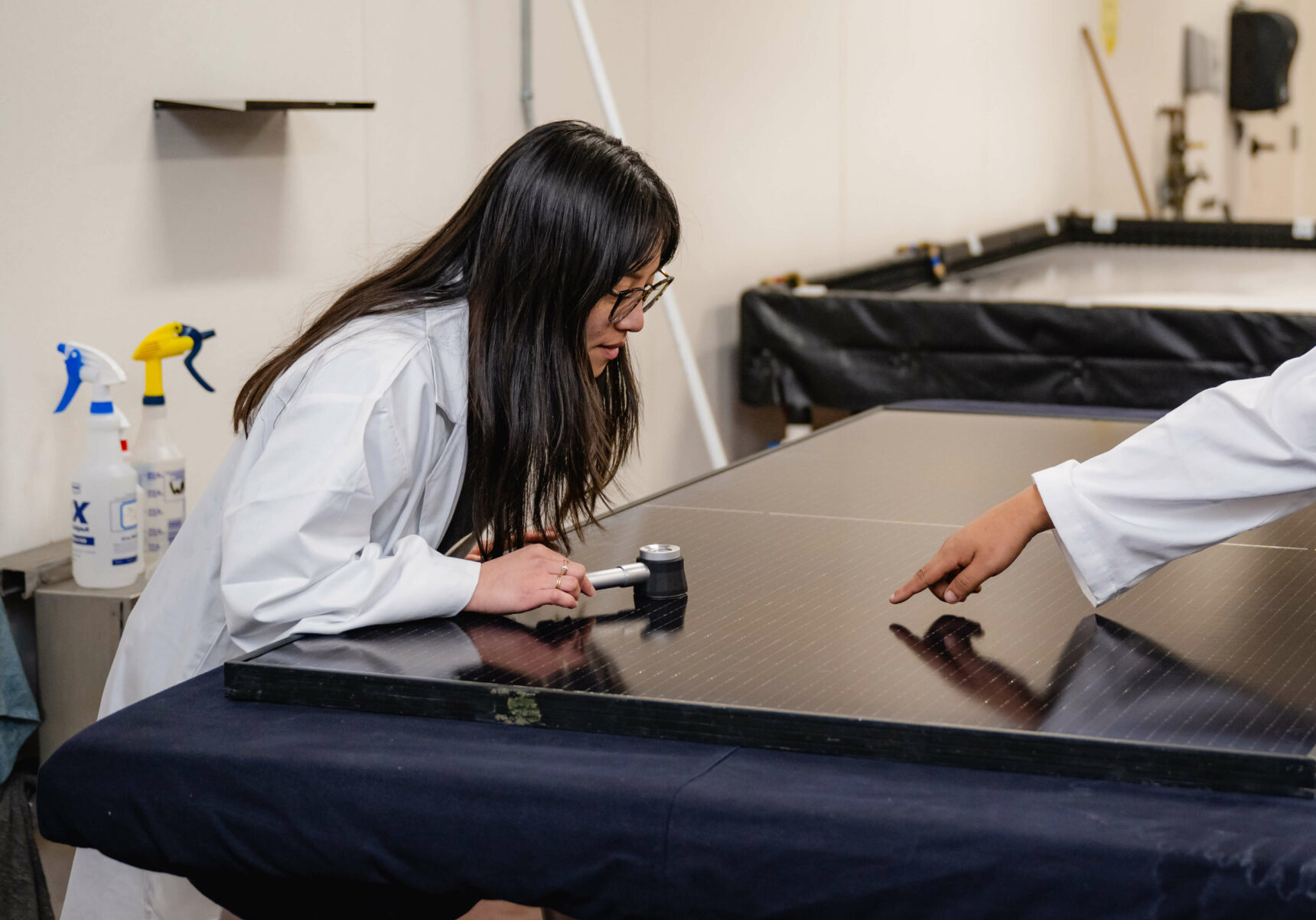

The BDS begins with exposing glass//backsheet modules to 1000 hours of damp heat, which weakens bonds in susceptible polymer backsheet materials. This is followed by rear-side UV exposure, 50 thermal cycles (TC), and 10 humidity freeze (HF) cycles. This sequence of UV, TC and HF testing is repeated twice more, followed by a short UV exposure for photobleaching, which removes a specific form of discoloration that occasionally happens in laboratory environments, but not in the field. Throughout BDS, PVEL performs visual inspection, electrical insulation resistance testing, and colorimeter measurements at ten different backsheet locations for two identical samples per BOM.

These colorimeter measurements use the Commission Internationale de l’Eclairage (CIE) L*a*b* coordinate system, with b* representing the yellow/blue coordinate. As material yellowness increases, so does the b* value. Calculating the difference between b* values (“delta b star”) at the beginning and end of BDS testing provides a marker for backsheet discoloration and potential material degradation.